Yesterday was an intensive day of work with some transcendental experiences.

A quick visit to the moromi while on the Toji’s round in the morning. Much foamier today.

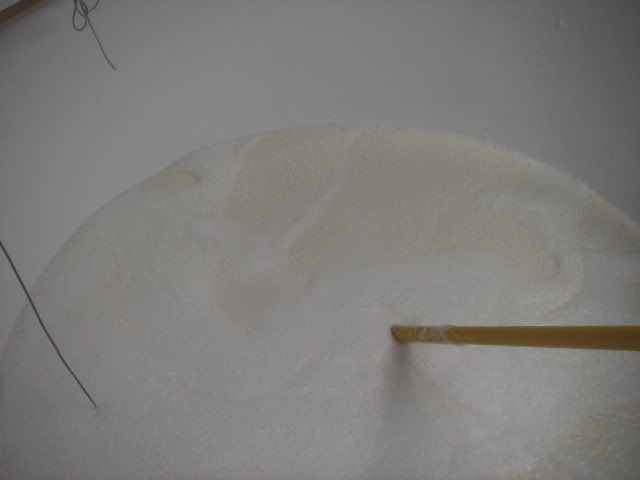

Preparing the rice for steaming.

Transferring the moto – the yeast starter – to a larger vessel to make the first mash, the odori – the dancing mash.

In action.

Adding spring water to the mash.

Adding steamed rice to the mash.

Now to prepare a fresh batch of moto. On this tray, toji has lactic acid (they do no kimoto or yamahai sake here), callate, calcium, and two ampoules of yeast #901 – the non-foaming variant of #9.

And so the moto begins.

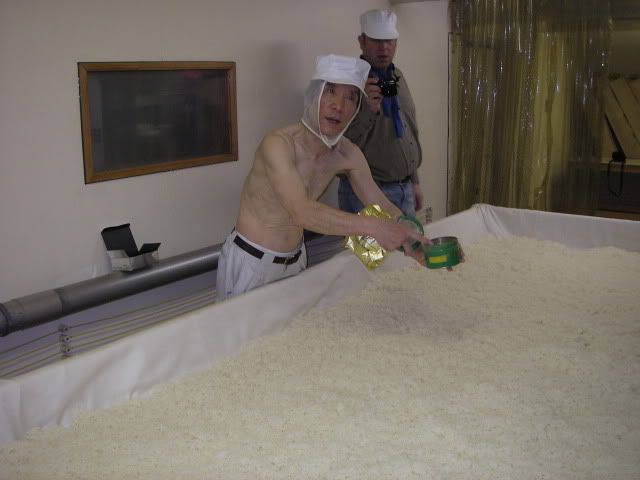

Adding koji-kin to the moto.

Shoveling out the freshly steamed rice.

The steamed rice is spread out on wire frames and then we quickly try to break up the clumps and drop the temperature. For each batch of rice we removed, there is a specific temperature goal before it is used – higher for the moto, higher still for the koji, lower for the odori. When the temperature is achieved, like clockwork it gets used.

Rice going into the odori.

Washing the linens that the steamed rice was transferred in.

Steamed rice spread out in the koji room, at a balmy 32 degrees centigrade.

One batch of sake was pressed today. The first several hours is free-run sake, and this is the collecting vessel.

Transcendental Sake Experience #1. Right at the source. Undiluted. Unfiltered. Un pasteurized. Within seconds of birth.

Post-transcendental experience. Packaging sake kasu – lees – into 20kg bags. The kasu are sold on to a tsukemono maker – Japanese pickles.

Spreading the koji mold.

After spreading the mold, the rice is mixed and moulded into a koji mountain, and bundled for propagation overnight.

And that was the day’s work. After a couple of beers, we went out to a local izakaya for dinner, and Daimon-san brought along several bottles of sake. I can’t get into details, but suffice it to say, it defied pretty much every conceived notion I’ve had about aged sake. In a blind tasting, Daimon-san asked us to identify age, alcohol content, junmai or not, milling grade, rice, and yeast. No one came close. I was off by, respectively, a factor of 6, 3 degrees, wrong, 5%, completely wrong, and, well, I got the yeast sort of right… it was the foaming version of #9.

What a day!

Go to Mukune Internship - Day 3

Wednesday, March 11, 2009

Mukune Internship - Day 2

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment