Some of Mukune's many offerings.

Bottle washing machine.

Bottle drying rack.

Filling machine. They haven't done any filling while we've been here.

However, there have been lots of filled bottles.

Cylinders of distilled alcohol for honjozo style sake. 95% abv.

A view towards the restaurant reception, from the brewery floor.

The reception area.

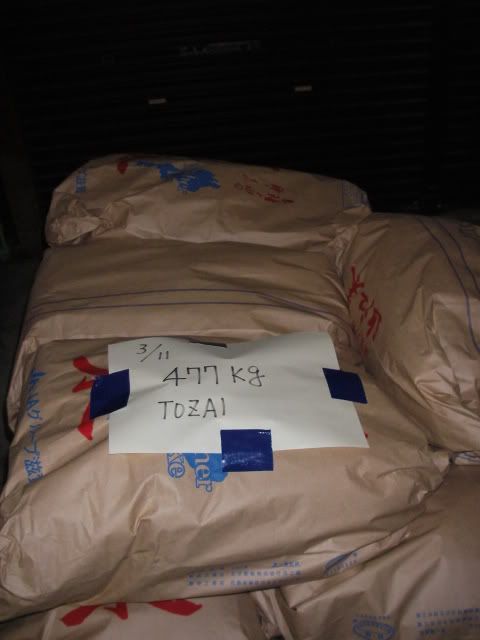

Bags of sake kasu - lees.

Spent a part of the morning cleaning up around the Yabuta - pressing machine.

And the remainder transferring the koji. Here, Kashira is loading the rice into the separator. My task was to handle the rake... I was sort of Koji Croupier in the Sake-land Casino.

Transferring the koji rice to the robot room.

The venting of the steam from the rice. Prepared the last batch of rice for the batch of sake that, apart from the beginning of the yeast starter, our group has had a hand in every step of production.

Bottle washing.

A whisk for use with sake made with the foaming type of yeast. While non-foaming yeasts are new, there has been widescale conversion to these types because it is cleaner and allows larger batches of sake to be made.

The cold storage room, where the super premium stuff is stored.

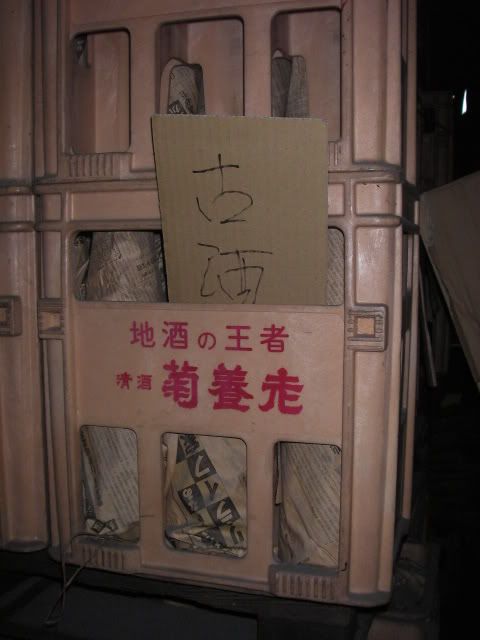

Koshu - old sake

It's a beauty!

Mountains of Koshu!

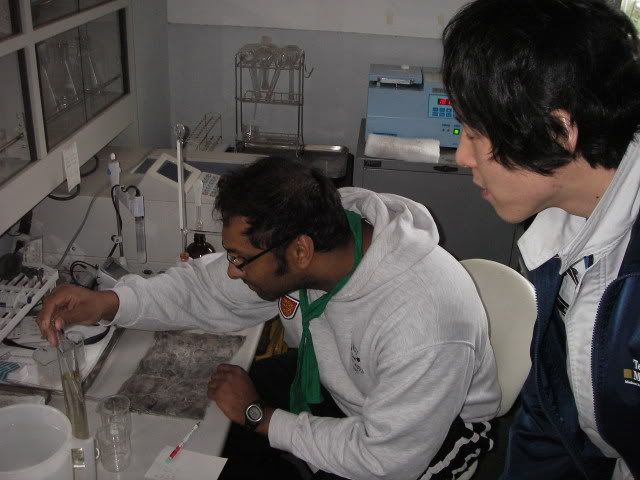

And now for the sake geek's dream afternoon... in the lab!

Measuring nihon-shu-do for Batch 11, a junmai daiginjo. Must be done at consistent temperature, so I had to warm it in a bath.

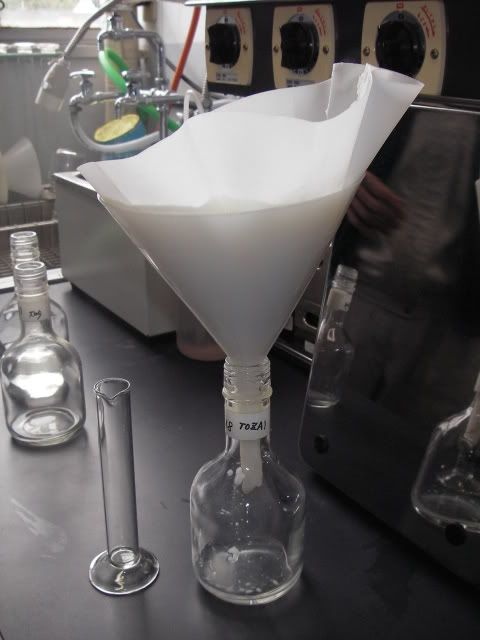

Withdrawing a sample for alcohol analysis.

The new device.

The old way, a sort of distillation set-up.

Siphoning sake for analysis.

10ml into two beakers, for acidity analyses.

Adding Sodium Hydroxide to neutralise the acid.

Doing the amino acid analysis.

Good times!

Testing Batch 18 shikomi... didn't taste great... yet.

And that's the end of the day's work. Party time approaches... time for a power kip.

Go to Mukune Internship - Team Party

Saturday, March 14, 2009

Mukune Internship - Day 5

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment