A busy Friday morning in the kura. Preparing to steam rice for the main mash. This is a heavy load so instead of manually cooling, we'll be using the conveyor today. A specialised "basket" is used to facilitate removal after the rice is steamed. A smaller portion of steamed rice, for starting a new batch of koji rice, was also made and cooled manually.

The odori moto being moved to a larger tank

Ice is used to rapidly cool the mash.

Steaming completed, and preparing to take out the rice.

Attaching the loops to the crane.

Moving to the hopper.

The rice is air cooled on the metal mesh conveyor belt, but we must manually break up any clumps. At the end of the belt, an air compressor shoots the rice almost the entire length of the brewery and directly into the main mash.

Freshly steamed rice for the main mash.

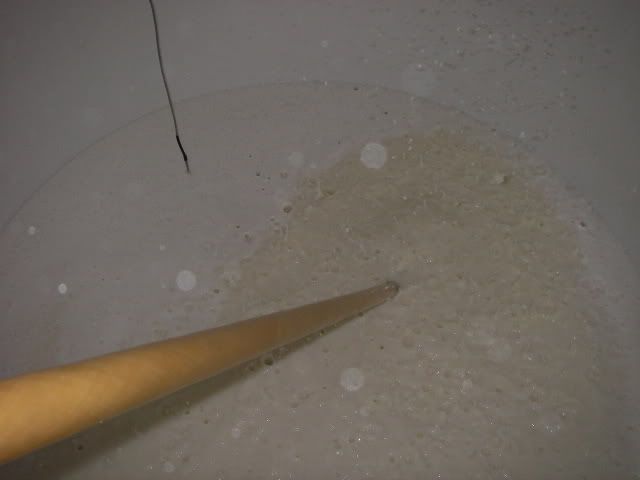

The main mash with the steamed rice being delivered at great speeds. After lunch, more rice washing and packaging.

This is Kashira - the operations chief... young guy... vacuum drying the washed rice which will be steamed tomorrow.

This koji rice, having finished its mold saccharification process, is removed from the "robot".

The rice is then transferred to large frames to dry out until use (tomorrow).

Spreading out the koji rice.

Up close.

And now, sprinkling the spores on the rice. I think I may just stay here.

The koji rice, having been sprinkled with spores, is mounded and wrapped to promulgate overnight.

And now, beer time, and then off to the izakaya.

Go to Mukune Internship - Day 4 Dinner

Friday, March 13, 2009

Mukune Internship - Day 4

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment